Tailored quality

From a builder of small warehouses to a constructor of steel structures with international customers: Kampstaal Staalbouw has come a long way since 1980. Four decades on we build more than just warehouses and industrial units – we deliver complex steel structures and highly challenging commercial and industrial buildings, both in the Netherlands and further afield. Our engineers, project managers, production employees and installers will work with you so that we can deliver quality that is tailored to your needs.

Management summaryOne-stop shop

Kampstaal Staalbouw invests continuously in its machinery. Amongst other things, we have a computer-controlled sawing/drilling line, a shearing/punching machine and an ultramodern cutting department at our disposal, which we use for activities including our specialism: cutting and welding huge castellated and THQ beams. This is work that requires space. Fortunately, Kampstaal has an 11,000 m2 production area and a 6,000 m2 steel preservation area. This gives us the space we need to work quickly and efficiently, as well as to respond quickly: we can take care of any last-minute changes with the utmost flexibility.

CE certification: future-ready quality

In 2012 Kampstaal Staalbouw became one of the first steel construction companies to obtain CE certification, even though CE marking for steel structures did not become mandatory until 1 July 2014. NEN-EN 1090 lays down the requirements for the CE marking of steel structures. Manufacturers who want to use CE marking on their products must have them tested in accordance with harmonised European testing standards. In addition to this CE certification Kampstaal owns the ISO9001 certificate for quality management and the VCA certificate for safety. And in June 2017 we received the ISO 14001:2015 certificate, which signifies we have a top-notch environmental management system.

- download EN1090-1 certificaat (Dutch)

- download DOP supplier (Dutch)

- download DOP structural design (Dutch)

- download extra DOP1 and DOP2 (Dutch)

- download ISO 9001 certificaat (Dutch)

- download VCA certificate (Dutch)

- download Safety Culture Ladder Certificate (Dutch)

- download ISO 14001 certificaat (Dutch)

Good preparation

You can only deliver custom solutions if you are well prepared. This preparation starts in our planning and control department. Each order passes smoothly through various departments: design engineers calculate complex steel structures and draughtspeople then use Tekla 3D draughting software to develop unique designs. Where possible, designs are brought together in BIM systems. In this way we keep lead times short and prevent duplicate work, while remaining particularly flexible when it comes to implementation.

Precision required

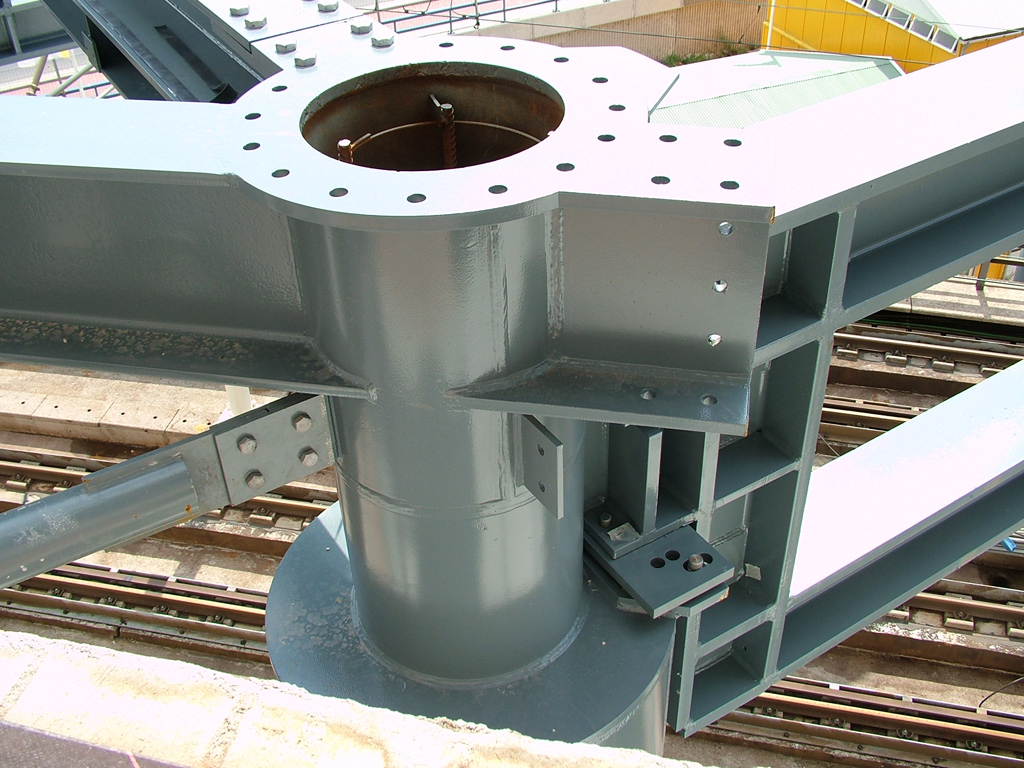

Custom solutions require precision. This is something we can guarantee by ensuring our planning and control department carries out the right preliminary work. Our design engineers calculate the stresses placed on a building and spread these stresses appropriately in the designs.

Planners translate these designs into plans and the machines and welders in our factory then set to work. The planners also order steel tubes, steel sheets and other types of structural steel. Profiles, sheets, angle steel and strip material can be cut economically, without compromising on quality.

Blasting & spraying

Preservation techniques ensure that our steel products have a long life. Each product is first blasted and then sprayed in any conceivable colour. The most popular colour is RAL 5010, an extremely durable shade of blue. We have a 4,000 m2 area where steel structures that have undergone such preservation processes can be left to cure.

Thanks to a unique extraction system, this hall is also suitable for working with water-based paints. Hot-dip-galvanised steel structures are also given one or more coats of paint or a duplex coating.

Contact

Want to know more?

Feel free to contact us.

Kampstaal B.V.

Distributieweg 10

8304 BJ Emmeloord

Postbus 1009

8300 BA Emmeloord

T +31 (0)527 69 80 20

KvK 39053026

Contact

Want to know more?

Feel free to contact us.

Locatie Meppel

Rabroekenweg 22

7942 JE Meppel

T +31 (0)527 69 80 20

F +31 (0)527 69 94 05